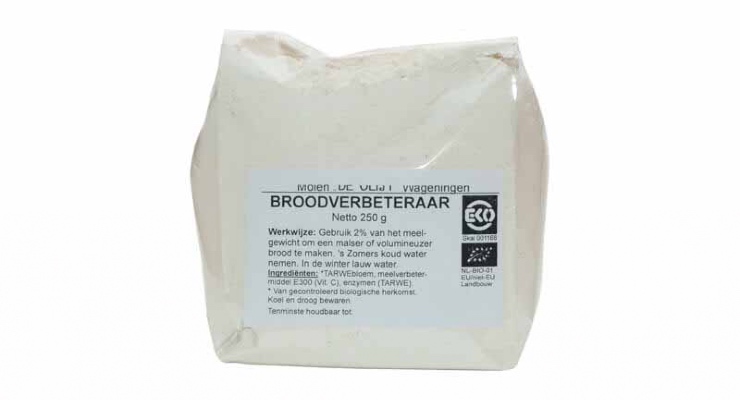

Bread Improver

In bakery industries around the world, "bread improver" preparations are intended to improve the quality of bread. They make the bread more flavourful and extend its shelf life. Due to their complexity and the fact that there are regulations governing their production, it is very difficult and virtually impossible for bakers to prepare them themselves.

Bread improvers are typically made by specialised companies that have the necessary expertise to produce these complex compositions. These additives are fully regulated by a Royal Decree in Belgium.

What is in a preparation?

There are usually 6 categories of elements in the preparation:

- Sugars

- Enzymes

- Dry milk ingredients

- Oxidizing & reducing agents

- Fats

- Emulsifiers

Sugar

Sugar serves to make the yeast work better and to colour the bread crust. However, not all sugars are converted by the yeast at the same speed. A preparation containing different types of sugars ensures that the yeast works optimally during the entire fermentation process. A mixture of sugars usually includes cane or beet sugar (sucrose), grape sugar (dextrose or glucose), fruit sugar (fructose), and milk sugar (lactose).

Enzymes

Enzymes are proteins that, when combined with flour and yeast, improve bread volume, shelf life, and tenderness.

Dry milk ingredients

Examples of dry milk include full milk powder, skimmed milk powder, buttermilk powder, or soy milk powder. The taste of the bread may vary depending on which milk powder you use. Dry milk powder also improves the colour of the crust.

OXIDIZING AGENT

OXIDIZING AGENT (Ascorbic acid or vitamin C) strengthens the gluten in flour, which can improve the rising process and accelerate the dough's rising time. REDUCING AGENT (L-Cysteine) is an amino acid that helps to relax and soften the gluten for better and easier dough handling.

FATS

FATS are an essential component of the preparation. They have a significant impact on the flexibility of the crumb, the volume of the bread, and the bread's ability to stay tender for longer. The dough becomes more elastic and less dry.

Emulsifiers

Emulsifiers are additives that strengthen dough, improve gas retention, and enhance volume. They also help distribute fats evenly throughout the dough.

Common emulsifiers include:

- Soybean-derived lecithin (E 322), which has a relatively weak effect.

- Monoglycerides (E 471), often used with bread improvers to create a softer crumb and lasting tenderness.

- DATEM (E 472e), commonly used in crunchy products.

- Sodium Stearoyl Lactylate (E 481), used in high-end bakery products to create soft crusts in yeast doughs.

By using emulsifiers in baking, bakers can improve the texture, consistency, and quality of their products.

The E's

The use and application of additives are regulated by an implementing decision of the European Union. The aim is to provide people with the most accurate information about what they are eating. Anyone who produces packaged food products is obliged to list the ingredients and additives on the packaging through print or labels. This is where we often see E numbers. What do they mean in practice?

- E100 to E199: Dyes

- E200 to E299: Preservatives

- E300 to E399: Antioxidants

- E400 to E499: Emulsifiers and thickeners

The E numbers are permitted in food by public health authorities and have been proven harmless, despite negative media attention.

Lesson 1 Lesson 3